|

Copper (and Nickel) Projects

Process Design

Sterlite Copper Smelter, Tuticorin, India Provided the front end engineering package for the converter aisle including anode furnaces. Worked closely with the Isasmelt primary smelting process designers. Subcontracted to Aker Powergas, Mumbai who constructed the smelter in 1996. Smelter has now been upgraded from the original design of 60 ktpa to over 300 ktpa.

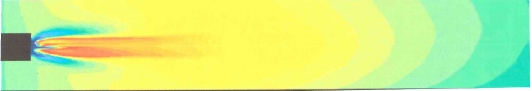

Supervised the modeling of a gas burner design by Kiln Flame Systems to replace the oil firing in the rotary calciner.

Prefeasibility Studies

Nkana Smelter, Zambia Advised the then owners Konkola Copper Mines (KCM) on the costs and design of an Isasmelt furnace to replace the existing reverberatory and El Teniente furnaces. KCM were subsequently sold to Vedanta who have built a single stage flash furnace to treat Konkola concentrates and closed Nkana smelter.

Norilsk Pyrrhotite A prefeasibility study was prepared to evaluate the viability of processing concentrates stockpiled at the Siberian plant. Nickel, copper and pgms would be recovered through a closed Italian smelter. The costs of rehabilitation and adapting the circuit were determined.

Engineers Reports

Due Diligence Conducted site visits as part of a multidiscipline team and reported on:

At the following copper smelters:

Audits

Conducted audits and provided an engineer's report covering similar topics to the due diligence on the following smelters:

Operations

Mufulira Div, ZCCM Zambia Mike was the Manager Metallurgical (1983-85) responsible for the operation and maintenace of the17 ktpd concentrator, smelter (35 MW electric furnace, PS converters 150 ktpa anode), two electrolytic refinery tankhouses (30 ktpm cathode), and the precious metals plant treating anode slimes from all the copperbelt tankhouses to produce gold, silver and selenium.

Rokana Div, Kitwe, Zambia The Metallurgical Superintendent responsible (1978-81) for Nkana smelter (250 ktpa anode) and refinery (tankhouse and wirebar furnaces) and metal sales for NCCM (including Nchanga electrowon cathode production).

Metallurgist on Nkana smelter 1968-71 and TORCO plant (fluid bed reduction of refractory copper ore) 1971-73.

Group Metallurgical Engineer ZCCM Responsible for technical aspects of all ZCCM concentrators and R&D department 1985-87.

|